Astore Keymak offer the full comprehensive range of thermoplastics welding equipment that compliments the thermoplastic pipes & fittings that we supply. This has assisted customers from all over sub-Saharan Africa to become successful in the widely differing industries. As a reliable, experienced supplier, we offer everything from Butt-welding, Socket Fusion, Electro-Fusion, Extrusion, Wedge welding, to IR welding equipment from worldwide Recognized, reputable and established suppliers.

- The jointing methodologies used in a pipeline construction is critical to the sustainability of the system. At Astore we are stockiest of cutting edge Welding equipment used for a variety of jointing methods.

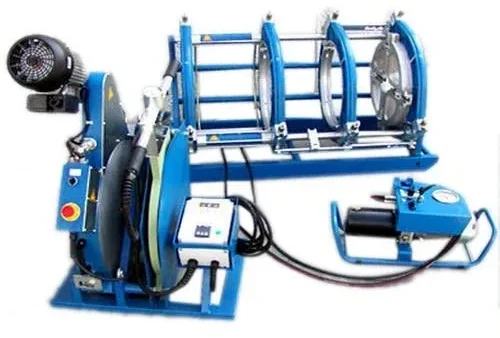

Butt-welding: Workshop Machines

- PL Workshop Series are hydraulically operated or CNC controlled for PE, PP, PVDF and other thermoplastic materials. Pivoting clamps allow for the fabrication of bends with different angles. These machines can be supplied with special clamps for fabrication of 90”, 45” and 60” tees as well as crosses.

- Sizes from 125-1600 mm

Butt-welding: Site Machines

- PT Trench Series are hydraulically operated butt welding machines suitable for PE, PE100, PP, PVDF and other thermoplastic materials. Self-aligning and very compact makes them suitable for working in road construction, ditches, aqueducts, gas ducts, and sewer as well as irrigation systems. PT series from PT125 to PT1600 are invented and patented by Techno due.

- Sizes from 40-1600mm

Bush-Ranger Machines

- This machine supplied from Techno due is a machine on tracks and can weld from 315-630mm, this machine can be adapted to suit your requirements if large sizes should be needed. The Bush- Ranger is self-motorized and remotely operated. This machine is equipment with two power sources, a diesel Generator to power the welding equipment and a further engine to drive the track system.

BUTT-WELDING MACHINES

Traditional butt welding brings the two workpieces together under high pressure as a first step. The contact area is then heated sufficiently to allow the applied pressure to bind the components together. Therefore, we can categorize butt welding as a single-stage process that makes use of current and pressure.

Supply Range:

- Butt-welders trench models from 40-2000mm diameter

- Butt-welding workshop Models from 40-630mm

- Machines operation availability in: Manual, Hydraulic & CNC

SHEET WELDERS

Traditional butt welding brings the two workpieces together under high pressure as a first step. The contact area is then heated sufficiently to allow the applied pressure to bind the components together. Therefore, we can categorize butt welding as a single-stage process that makes use of current and pressure.

Supply Range:

- Butt-welders trench models from 40-2000mm diameter

- Butt-welding workshop Models from 40-630mm

- Machines operation availability in: Manual, Hydraulic & CNC

SOCKET FUSION WELDING EQUIPMENT

Socket fusion welding is a widely used technique for assembling plastics piping systems using injection moulded fittings. Operating principles are straightforward, the welding cycle essentially consisting of a heating phase and a cooling/welding phase.

Supply Range:

- Weldable Size: 20mm – 110mm diameter

- Weldable materials: PP, PE, PVDF

- Machine operation availability: Manual, Lever & Hydraulic

AFTERSALES SERVICE & SUPPORT

Astore Keymak has the facilities & expertise to provide in house repairs & on-site repairs on our supply range of welding equipment. We provide full range of training, competency training, calibration and maintenance, service, and repairs on the welding equipment that we supply.